How to determine if bulk inventory management is right for you

A data-driven inventory management system is a vital component to the success of any ecommerce business owner.

But industry insiders also know that getting it right can sometimes feel more like practicing some kind of dark magic as opposed to a predictable, scientific process.

Especially given the rapidly changing world of online retail and the volatility of our current economic landscape, a “best-guess” approach to inventory management just doesn’t cut it anymore. Making a mistake in this area of your company’s operations could prove costly at best and detrimental at worst.

If this sounds a little overdramatic, it’s because inventory management is a dramatically important process.

A 2015 study conducted by the IHL Group found that businesses lost over $600 billion that year due to running out of stock, while dead stock contributed to another roughly $470 billion in losses: evidence that inventory management miscalculations can have a dire impact on ecommerce businesses.

Therefore, it’s crucial to study up on the best types of inventory management for your company to ensure its overall health.

This is where bulk inventory management comes into play. Bulk inventory management done well is the secret sauce of the most successful retailers. So how can you take a page from the Amazons, Etsys and eBays of the world and start implementing bulk inventory strategies in your organization?

Let’s start by defining our terms. Then, we’ll look into some hypothetical examples and best practices for maximizing your per-pallet revenue with bulk inventory management.

What is Bulk Inventory Management?

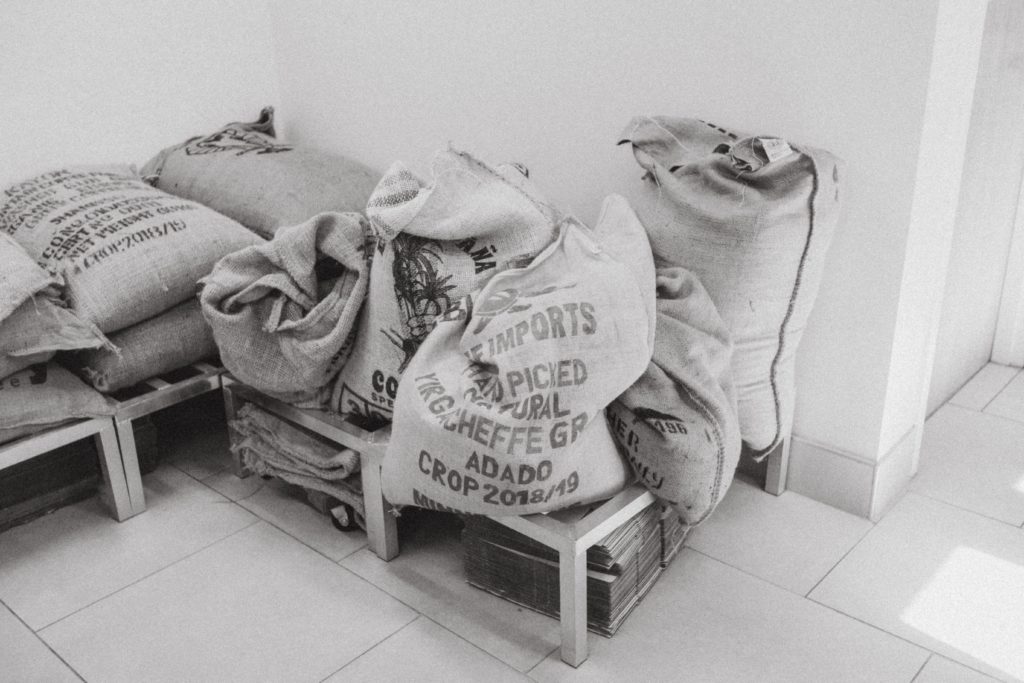

Let’s start with a basic definition: bulk inventory management refers to a three-part system that starts with a business ordering goods in bulk (the exact quantity is usually based on its sales forecasts).

That business contracts some sort of storage facility, whether it’s their own on-site warehouse or a third-party logistics establishment (3PL), to store those goods for the duration of the sales cycle.

Finally, as these stock reserves are sold and start to diminish in number, the business reorders at a specifically calibrated threshold to avoid going out-of-stock, and the process starts anew.

These thresholds are often referred to as “par levels.” We define par levels along with a bevy of other relevant industry terms in our blog post on ecommerce inventory management best practices.

Bulk inventory management—which some businesses might also refer to as wholesale inventory management—doesn’t just rely on forecasts, though that’s obviously key to the process.

It’s also crucial to keep track of current manufacturing and delivery times. This allows you to extrapolate how much “safety stock” your business should always have in reserve.

Is Bulk Inventory Management Right For My Business?

Bulk purchasing is a sound bet for several types of organizations, but especially for established companies (or ones on a solid path to growth). This is notably true if your organization has reliable methods for forecasting demand and profit.

Oftentimes, but not always, that means having a firm grasp on historical sales data and how things like seasonable variables affect product demand.

That being said, it’s not perfect for every situation—here’s a rundown of the main pros and cons:

The PROs of bulk inventory management

- It can help retailers save significant money through bulk discounts offered by most manufacturers. Those bulk discounts scale down the average cost-per-unit, which in turn scales up profits

- Compared to other purchasing methods, bulk inventory management is relatively straightforward to implement

The CONs of bulk inventory management

- Even though bulk-buying saves money at the moment of purchasing, it comes at the cost of having to rent (and staff) a warehouse or 3PL facility. Therefore, it’s not viable for many young businesses without access to storage. If you’re in that boat, try dropshipping or just-in-time shipping instead

- Most importantly, you’ll need to have laser-accurate sales forecasts. Otherwise, you’ll likely end up with costly dead stock on your hands

Once you determine if bulk inventory management is right for your business, there’s still a little more research and decision-making to do.

Namely, it’s important to determine specifically what bulk inventory tactics and processes your business would implement. Here’s a rundown of the most common techniques.

Bulk inventory management techniques

Par level or reorder point system

We’ll dig deeper into this in a little bit, but in brief: a business that adopts a reorder point system will reorder stock when its reserved goods fall to a specific number of units.

This threshold is determined via a precise calculation. Businesses that are moving fewer, less diverse types of goods typically rely on reorder point management.

Order pattern system

This is the simplest type of bulk inventory management, and as such, is usually right for companies that have very predictable sales patterns.

If you know you’re reliably going to make x number of sales a year, and that number has historically varied very little, then you can dispense with reorder point calculations and simply make a fixed bulk purchase at regular intervals.

This is only recommended for companies with a vast array of historical data and predictable seasonal demand trends (a holiday decor manufacturer, for example).

Control rhythm system

This technique is appropriate if your company has perfected the science of inventory forecasting and you feel confident about predicting future demand for your goods.

The control rhythm system is a more “hands-on,” real-time approach of auditing inventory levels at specific times throughout the year and tailoring your future purchase orders accordingly.

How to get started creating a bulk inventory management system

Setting up a sustainable and accurate inventory management system is no easy task—and given the potential consequences of miscalculations, it can definitely feel overwhelming at the beginning.

The good news is, as pointed out above, it’s actually pretty straightforward to establish a bulk inventory management system, especially if you automate the process with the help of inventory management software.

Even more granular, here are some practical action steps you can take to get started:

- Choose an inventory tracking system that’s right for the scale and scope of your company. There are several software platforms available to purchase, as well as open-source options that are free online. (SkuVault Core’s inventory management software is one option with a demonstrated track record for streamlining the processes of inventory management).

- Once your chosen program is up and running, enter the names and current number of units for each of your products into the system.

- Make sure inventory is adjusted for each product that gets sold and shipped to a customer. Then adjust inventory again whenever a new order of goods comes in. (Note that much of this is automated when you use an IMS).

- Scan in returns and make sure your inventory also reflects the number of those returned units as they come in.

- Make it a regular practice to reconcile your inventory with your IMS to make sure your numbers are accurate.

- Set up an alert in your inventory management program to inform you when it’s time to reorder (based on whichever of the above-listed management methods you’re using).

Replenishment alerts in SkuVault Core are set once and continue in perpetuity, allowing merchants to get back to high-level business decisions.

The intelligent Replenishment Report feature will even parse out which products need to be reordered in what quantity based on forecasted customer demand.

SkuVault then generates a custom-tailored PO that you can send to your manufacturer, saving all the tedium of making those calculations manually.

Avoiding the Pitfalls of Inaccurate Bulk Inventory Management

It’s not enough to simply set up the structure of an efficient, responsive bulk inventory management system and then abandon it, hoping for the best.

An inventory system that isn’t maintained will grow weeds. In other words, it will become irrelevant and inaccurate.

As advanced as IMS platforms are, you still need to stay on top of fluctuating factors like delivery times and shifting consumer demand in order to maximize your ecommerce revenue.

Here are a few case studies of bulk inventory management to mitigate some of the most common errors.

Reorder point example

Let’s revisit the reorder point system introduced above.

Many retailers depend on a reorder point formula to know when they should re up their stock (without ordering too much).

Keep in mind that it’s not quite as simple as reordering as soon as your reserve of products has hit a critical safety threshold—you also need to take into account inventory delivery time, so you don’t go out-of-stock before the new products arrive.

This handy formula has that time cushion built in:

(Lead time in days x average daily sales volume) + safety stock

This concept is best illustrated with a real-life example.

Let’s say you’re selling glazed ceramic bowls. You usually sell five of them a day, and have a goal of maintaining forty ceramic bowls in stock at any given time. When you reorder those bowls, it takes two weeks for them to arrive and be prepared to ship back out to your customers.

Now, simply plug those numbers in: (14 days of lead time x 5 daily sales volume) + 40 safety stock = 110 ceramic bowls. And that’s it: you’ve established your reorder point.

As soon as you have 110 bowls left in stock, you know it’s time to replenish your stock.

Granted, this is a simple example. If you sell multiple product lines, you’ll want to establish your reorder point or par levels on a SKU-by-SKU basis.

Lead time and lead time demand

Your reorder point is woven into some other key metrics in your IMS. Namely, your lead time demand, or how long it takes for goods to arrive at your warehouse from the time of placing the order, as well as how much customer demand there’s going to be throughout that lead time period.

See where things can start to get a little complicated?

Just like with your reorder point, if you err in calculating lead time demand, you also run the risk of going out-of-stock (or ending up with dead product on your hands).

Here’s a handy formula for calculating your lead time:

Lead time demand = lead time x average daily use

Calculating lead time demand helps you pad your safety stock and replenishment orders so that you don’t run out of stock during the manufacturing and shipping process.

More tips for efficient, streamlined bulk inventory management

Now that you’ve got a handle on the basic nuts and bolts of bulk inventory management, there are a few more best practices you can implement to ensure your business stays on the road to healthy growth.

Reduce your carrying costs

There’s no way to get around your business’s carrying costs, which include things like capital investment, taxes, insurance, rent and employee cost of running your warehouse or 3PL facility, and more.

But there are ways to help lighten the load. Key among them is getting the most out of your storage facility. If you’re contracting with a 3PL for your storage space, for instance, can your contract be renegotiated after a certain timeframe?

Also take a look at your vendor contracts—over time and as you build stronger relationships, see if you can renegotiate more advantageous terms. Another option is to share warehouse space with another vendor and split the cost.

You’ll quickly realize that carrying costs can get out of control, especially without an inventory management strategy. Always strive to be examining, optimizing, and asking yourself, “How can I make this cheaper?”

Automate as much as possible

Automation not only saves you time, but mitigates human error from your inventory management practices. That’s where bulk inventory management tools like SkuVault come in, which can help you automatically calculate your lead time demand and reorder point numbers, keep your inventory numbers up to date as product moves in and out of the warehouse.

A robust IMS like SkuVault can also take over repetitive manual tasks related to purchasing like automatically reordering items and generating purchase orders.

We’ve built SkuVault with an eye to help ecommerce business owners maximize their revenue through intelligent inventory management.

Conclusion

SkuVault’s cloud-based platform gives users real-time information and easily accessed insights into their inventory along every step of the inventory management cycle. Further, we’ve got a proven track record of improving inventory management accuracy and efficiency for organizations of all sizes.

Whether you choose to implement bulk inventory management or some other strategy, SkuVault will do the heavy lifting for you, converting your ecommerce pain points into profits.

We’d love to show you how simple it is to transform your organization’s inventory management practices. Sign up for a live demo with our team today.